Welding is a manufacturing or assembling process that is used to join materials such as metals and thermoplastics. Metals and thermoplastics are joined together by fusion of the intersecting materials. Welding is an evolving technology. Commonly implemented welding technologies include shielded metal arc welding (SMAW), gas tungsten arc welding (GTAW), gas metal arc welding (GMAW), flux-cored arc welding (FCAW), and submerged arc welding (SAW). Materials used in the welding process are collectively termed welding consumables. Usage of consumables depends on the welding technology implemented. However, commonly used welding consumables are stick electrodes, solid wires, flux-cored wires, and SAW wires and fluxes. Stick electrodes and filler materials such as solid wires are used during the welding process, while flux and welding gases are employed to prevent the oxidation of base materials. Welding consumables are employed in various applications in end-user industries. However, different types of welding technologies are implemented according to the needs of end-users; usage of products depends upon the nature of the application.

Demand for welding consumables, especially electrodes, was high in Indonesia in 2014. Stick electrodes was the largest product segment of the welding consumables market in Indonesia and accounted for over 50% of the market share in 2014. This can be attributed majorly to the low cost and high usage of the manual welding process in the country. However, the welding industry has been experiencing a shift from electrodes toward solid wires and flux-cored wires owing to higher production efficiency. Wires and fluxes are gaining popularity over electrodes. Demand for welding consumables in the welding industry is driven by factors such as less wastage, suitability for automatic welding systems, higher productivity, and wide usage among different welding technologies. Flux-cored wires and SAW wires and fluxes are anticipated to be among the rapidly growing product segments during the forecast period.

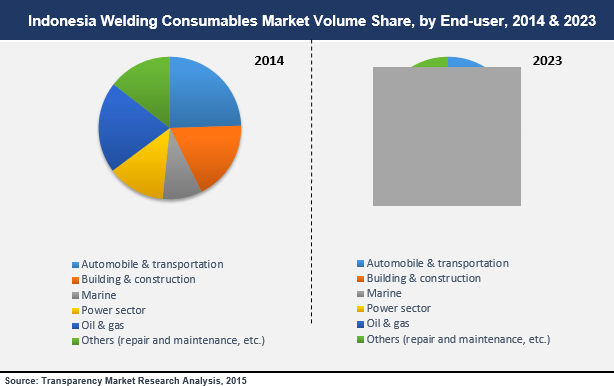

Key application sectors of welding consumables in Indonesia include automobile & transportation, building & construction, marine, power, oil & gas, and others (repair & maintenance). Growth of end-user industries is likely to augment the demand for welding technologies. Expansion in the automobile & transportation sector is anticipated to be a major factor driving the welding consumables market in Indonesia. Production of cars is set to outpace sales during the forecast period, as global carmakers are strengthening domestic output. The welding consumables market is expected to benefit from this, as automotive is one of the key end-user industries in Indonesia. Various materials such as steel, glass, rubber, copper, aluminum, and plastics are used in different parts of a vehicle. Metals employed in the manufacture of automobiles are joined through different methods. These include temporary methods such as bolts, screws, and rivets, and permanent methods such as welding. Automotive & transportation was the largest end-user segment of the welding consumables market in Indonesia in 2014. It held 24.5% share in 2014. Furthermore, demand for welding consumables in the power sector in Indonesia is increasing at a rapid rate owing to rising electrification rate and capacity additions in the power sector in the country.

The value chain depicts a high degree of forward integration in the welding consumables market in Indonesia. Large numbers of players operate in the market. Key market players include Lincoln Electrical Holdings Inc., The Linde Group, Inc., PT. Ispat Indo, PT. Gapura Raya, PT. Alfa Metalindo Indonesia, P.T. Intan Pertiwi Industri, PT. Cahaya Las Mandiri, PT. Yontomo Sukses Abadi, Nikko Steel, and Voestalpine AG

Chapter 1 Preface

Chapter 2 Executive Summary

Chapter 3 Industry Analysis

Chapter 4 Market Segmentation – Product Segment Analysis

Chapter 5 Market Segmentation – End-user Analysis

Chapter 6 Company Profiles

Chapter 7 Primary Research – Key Findings

Welding Consumables (Stick Electrode, Solid Wires, Flux-cored Wires, SAW Wires & Fluxes and Others) Market Forecast 2015 - 2023