Set to grow at an impressive pace of a double digit compound annual growth rate over the forecast period of 2015 to 2023, the global nanocellulose market is on its way to a higher valuation. One of the biggest attribute that goes in favor of this market is the superior properties of the products. Additionally, it is quite important to note here that its increasing adoption in flexible packaging aids is also contributing to growth in the market.

As per Transparency Market Research, the sturdy growth curve that would be noted over the forecast period would lead the market to a host of new growth opportunities. And, demand from pharmaceuticals and cosmetics would be major contributor of growth in the market.

A glimpse into notable developments shaping the market landscape and into trends and drivers that are helping the market stay on an upward facing growth curve is provided below:

Nanocellulose is a lightweight material obtained from wood pulp or plant cellulose. The term generally refers to cellulose derived nanofibrils that can be long ribbon-like, short rod-shaped or thread-shaped. Nanocellulose is obtained through mechanical or chemical treatment of cellulose, a biopolymer material abundantly available across the globe. Nanocellulose offers immense growth potential owing to its superior mechanical, thermal, rheological, and structural properties vis-à-vis other cellulose-based derivatives and nanomaterials. Unique properties of nanocellulose include high aspect ratio, biodegradability, high strength, and low density. Nanocellulose can be employed in virtually every field. It can be used as rheological modifier in oilfield chemicals and oxygen barrier in packaging films.

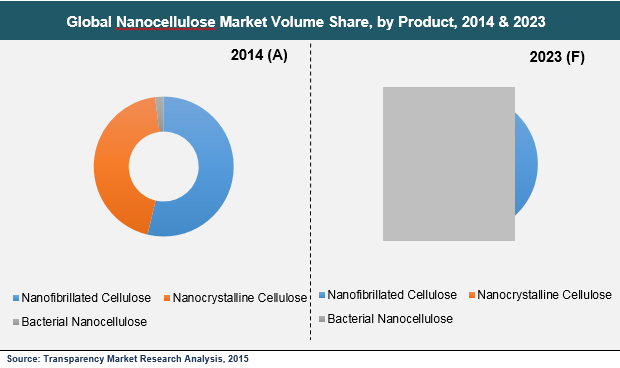

Nanocellulose is further classified into nanofibrillated cellulose, nanocrystalline cellulose, and bacterial nanocellulose. Nanofibrillated cellulose accounted for the largest share (over 50%) of the global nanocellulose market in 2014. Nanofibrillated cellulose is manufactured through a series of mechanical treatments. This includes homogenization, microgrinding, and microfluidization, followed by enzymatic treatment and oxidation. Nanofibrillated cellulose can be employed in various end-user industries such as paints & coatings, paper processing, composites, oil & gas and adhesives. Nanocrystalline cellulose accounted for the second-largest share of the nanocellulose market in 2014. It can be used in packaging films, textiles, and personal care products. Bacterial nanocellulose held the lowest share of the market in 2014; however, it is expected to be one of the fastest growing product segments during the forecast period. Bacterial nanocellulose offers immense potential in the fields of biomedical implants and drug delivery systems.

Composites, paper processing, paints & coatings, and food & beverages were among the key end-users of nanocellulose in 2014. Composites was the largest end-user segment of the nanocellulose market and accounted for more than 35% of the market share in 2014. Nanocellulose is used in composites owing to its high strength and low density. Nanocellulose-based composites can be used in automotive, aerospace, and construction components. Nanocellulose is employed as rheological modifier and emulsion stabilizer in paints & coatings, food & beverages, and oil & gas industries. Other end-users of nanocellulose include electronics, biomedical, pharmaceutical, and textile industries. Nanocellulose can be used in the formation of flexible displays and drug delivery systems.

Extensive support and funding from governments and organizations is primarily driving the nanocellulose market. Countries such as the U.S., Canada, Japan, Sweden, and Finland have been increasingly supporting the development of nanocellulose. Nanocellulose has the ability to lower carbon footprint, as it is a product of renewable sources. Despite its significant potential, factors such as scaling up issues, high energy consumption, lack of consumer awareness, and lack of product standardization and quality are expected to hamper market growth in the next few years. Nanocellulose is likely to provide numerous opportunities in flexible electronic displays, pharmaceutical formulations, and non-woven products and tissues.

In terms of volume, North America is projected to exhibit the fastest growth rate in the nanocellulose market during the forecast period. Technological advancements and governmental support have been the key factors driving the nanocellulose market in the region. Europe accounted for the second-largest share of the global nanocellulose market in 2014. Market penetration in regions such as Asia Pacific, Latin America, and Middle East & Africa is low as compared to North America and Europe due to lack of product awareness and technological issues. However, this scenario is likely to change in the near future.

Key manufacturers of nanocellulose include CelluForce Inc., American Process Inc., Innventia AB, UPM-Kymmene Oyj, STORA ENSO, DAICEL FINECHEM LTD., and Nippon Paper Industries Co., Ltd.

Chapter 1 Preface

Chapter 2 Executive Summary

Chapter 3 Nanocellulose Market – Industry Analysis

Chapter 4 Raw Material and Price Trend Analysis

Chapter 5 Market Segmentation – Product Segment Analysis

Chapter 6 Market Segmentation – End-user Analysis

Chapter 7 Market Segmentation – Regional Analysis

Chapter 8 Company Profiles

Chapter 9 Primary Research – Key Findings